Latvijas Finieris Reaches 100 Lignin Adhesive Tests, Advancing Natural Production Technologies

This month, the Product Research Laboratory at AS Latvijas Finieris completed its 100th trial of a naturally-derived adhesive with the potential to play a key role in future plywood manufacturing. This achievement represents strong progress towards the company’s goal of developing more environmentally friendly, naturally sourced technologies and reducing reliance on fossil-based raw materials.

The development of lignin-based adhesives forms part of the international VIOBOND project. As part of this project, Latvijas Finieris is constructing a new resin production plant for its chemical products in Riga – an installation that will be unique not only in Latvia but also internationally. It will scale up the production of a new type of resin, in which part of the fossil-based raw materials, phenol and formaldehyde, are replaced with lignin – a naturally occurring component of wood. This innovation significantly reduces reliance on fossil resources and fosters a more sustainable approach to adhesive production. The mill will have an annual production capacity of up to 45 000 tonnes. This project will enable the replacement of fossil-based adhesive components with renewable materials, making a significant contribution not only to the company’s sustainability but also to that of the industry as a whole.

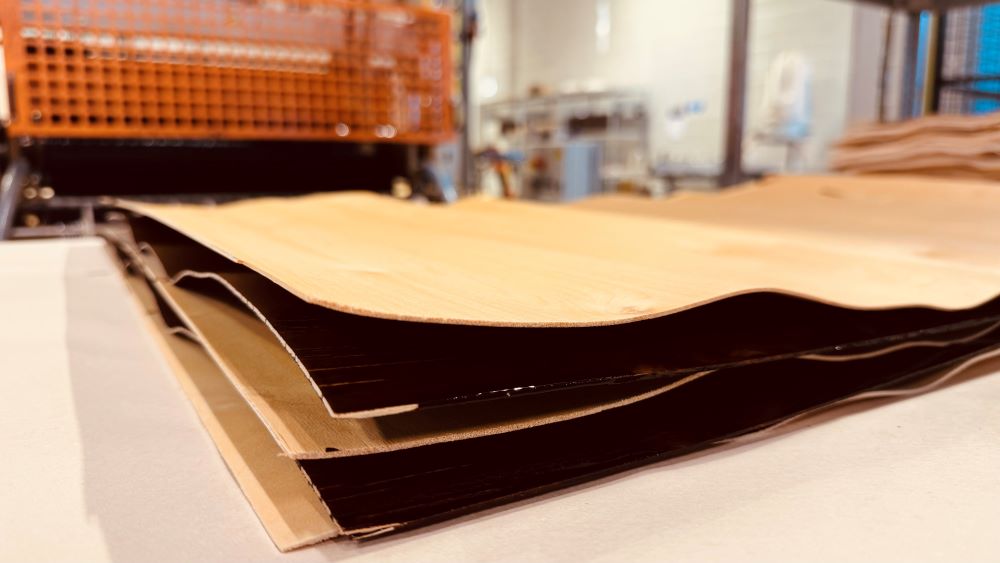

The new adhesive is based on lignin, a natural polymer found in wood and other plants, predominantly within their cell walls. Together with cellulose and hemicellulose, it constitutes the fundamental structural components of wood. Lignin acts as a natural ‘glue’ that binds the fibres of the cell wall, giving plants their toughness and mechanical strength. Latvijas Finieris purchases lignin in a pre-processed form for use as a base material in the production of LPF resins. Adhesive development in the laboratory is a highly intensive and meticulously controlled process. Researchers evaluate an average of four different formulations and bonding technology regimes per test cycle, assessing their durability, manufacturability and long-term sustainability. The next steps will involve in-depth testing and the demonstration of the selected adhesive formulations under real industrial conditions once the new resin plant comes on stream in 2026.

This activity is part of the HORIZON 2020 co-funded project “VIOBOND”, which promotes the transition to more sustainable and bio-based industrial production in Europe.